- Home »

- Products »

- ComColor® series »

- ComColorExpress FS2000C

| |

| Maximize the performance of ComColor to enhance your production print operations. Support a wide variety of needs, such as variable data printing operations. |

|

|

The ComColorExpress FS2000C leverages the full potential of ComColor printer, bringing greater efficiency and flexibility to printing operations, In addition to supporting a wide variety of needs, such as variable data printing operations that are vital to direct marketing, the FS2000C maximizes the performance of ComColor so that you can meet the diversified business demands of high-mix, short-run printing with quick turnaround. The combination of advanced RIP technology and a wide selection of printing functions make the FS2000C a powerful production print solution that can expand your business possibilities.

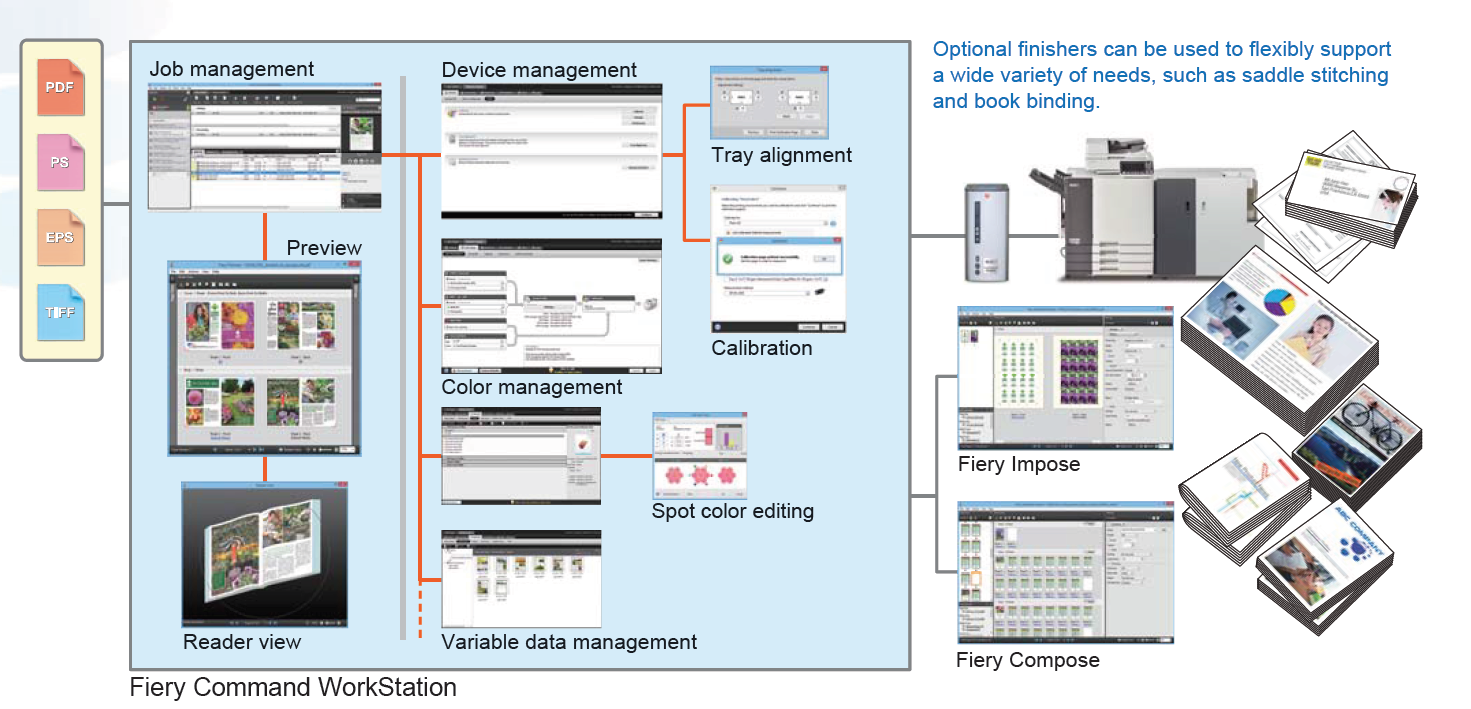

The FS2000C can also be used with management tools such as the industry-leading Fiery Command WorkStation software developed by EFITM. With the ability to manage and edit print jobs and server functions, you can create the exact environment for your production print operations. | |

| |

| Architecture that delivers high-speed data processing The FS2000C utilizes Fiery SmartRIP technology that maximizes CPU performance and accelerates RIP processing. Superior performance is achieved with efficient processing that maintains high productivity while ensuring the accuracy of large-volume, complicated document data. SmartRIP SmartRIP technology accelerates color compression and rendering, and achieves even faster processing when used in combination with Adobe PostScript 3. |

Leverage the full potential of ComColor GD series The FS2000C takes full advantages of the superior performance of ComColor GD series, such as the world��s fastest printing speeds with low running costs. In addition, complicated tasks can be incorporated into and in-line process by using optional equipment such as the Perfect Binder for assembling books with covers, or the Wrapping Envelope Finisher for printing, enclosing and sealing items in envelopes. Furthermore, the paper feed unit features a straight path, which enables support for a wide range of paper types and provides easy maintenance in the event of a paper jam. |

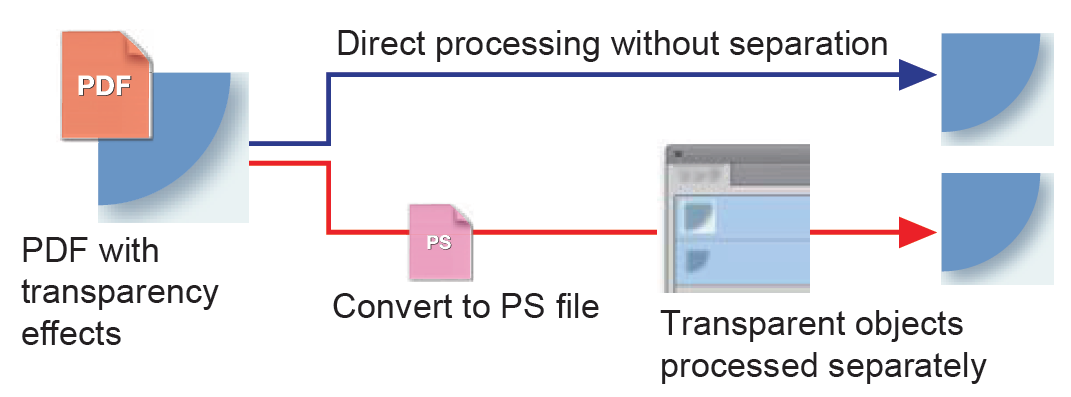

Adobe PDF Print Engine 3.0 PDF files can be processed directly, without converting to PostScript. From design to print, this provides a native PDF end-to-end workflow that ensures consistency across all stages. In addition, PDF files that contain transparency effects can be processed and output directly as a composite, rather than as separations. As a result, the errors that may occur when printing PDF files are dramatically reduced. |

|

| Effectively support a variety of needs with the ComColor's high-speed printing Fiery Command WorkStation provides total management of print jobs and devices | |

| The FS2000C features the Command WorkStation interface, which enables total management of print jobs and server functions. This comprehensive management tool integrates a variety of functions into a single application, with features such as the Job Center for managing print jobs, and the Device Center for configuring color controller settings and accessing various print management tools. | |

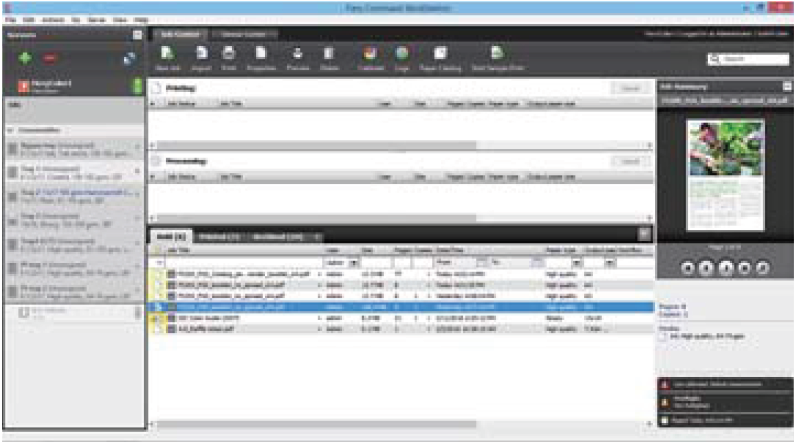

Job management You can modify the print settings of submitted jobs, change the print order, and display previews on the fly. With the ability to view the current jobs and their status on the screen, you can perform integrated management of all jobs processed by the print controller. | |

| |

| Main features 1. Drag-and-drop interface Drag-and-drop interface enables you to import print jobs simply by dragging and dropping files and folders. 2. Scheduled printing Scheduled printing function enables you to define when jobs will print by setting date and time parameters. This can help eliminate delivery delays caused by an operator who forgets to print a job at the required time. 3. Print interruption for rush jobs Print interruption for rush jobs function enables you to interrupt the currently printing jobs to print a different job. 4. Job merge function Large documents such as user manuals or research papers consisting of data separated into chapters from separate sources can be combined and printed all together. 5. Preview function Using the preview function to see exactly how the job will look before RIP processing. 6. Virtual Printers and Server Presets Configuring settings for a specific purpose and using them as a printer driver is possible. By saving complicated settings as a template, you can automate the preparation process for print jobs. | |

Device management The Device Center integrates a variety of functions necessary for managing devices, such as viewing and modifying the default settings of print options, configuring settings for fonts, workflows, colors, Paper Catalog, and managing spot colors and variable data printing (VDP) resources. The functions are conveniently located together in the same area, making it qick and easy for you to configure and manage the color controller settings. | |

| Main features 1. Tray alignment If misalignment occurs when printing on standard size paper, you can adjust the printing position and apply the changes to all subsequent print jobs. 2. Color Management Color management function enables you to specify different color profiles for each color space and designate them as the default print settings. 3. Paper Catalog Paper Catalog function enables you to create a database of usable media. The output tray, media thickness, and type details are automatically applied, eliminating operation errors. 4. Spot colors Creating new custom spot color definitions or editing color values while viewing the print results on the screen is available. | |

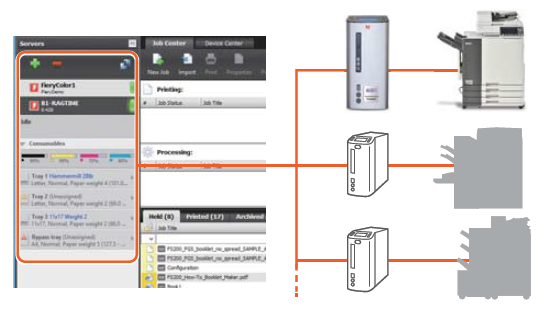

Server management Command WorkStation enables you to perform total management of Fiery servers, even when multiple servers are connected. Thesse functions include the ability to connect or disconnect servers and check information such as their operating status. | |

| |

|

|

|

Copyright 2016 @ RISO Hong Kong. All rights reserved.